The other day I mentioned the MagAO-R project, which is MagAO-Refurbishment. Here I describe the glycol leak that happened on Feb. 19th 2016 and the recovery and refurbishment of MagAO as of today. The good news is that the ASM is recovered and refurbished! Here is a 5-second video showing the MagAO ASM running again:

And here is the saga:

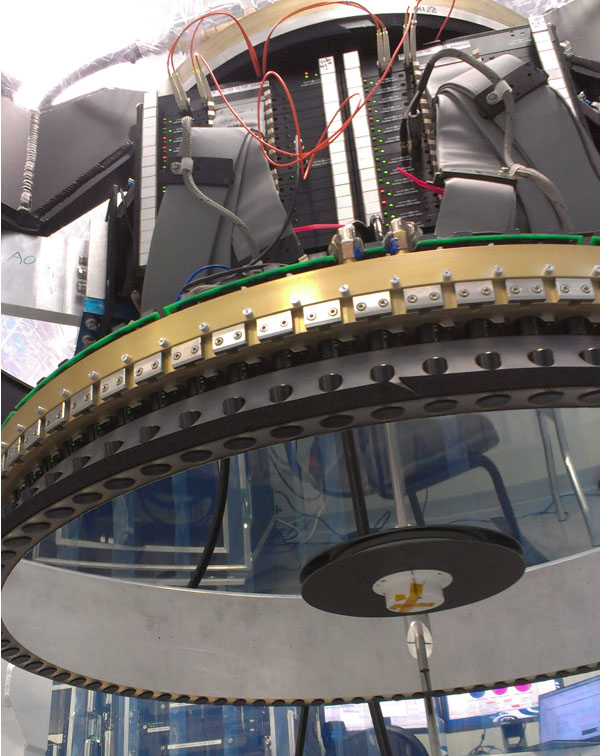

Did you know that MagAO’s adaptive secondary mirror (ASM) has 585 actuators, each of which has a capacitor to measure its height from off the reference body at a 70 kHz rate? And the actuators are controlled in 6 sectors with 3 crates of electronics controlling 84 DSP boards. This means a lot of electrons are flowing, using a lot of power, which generates a lot of heat:

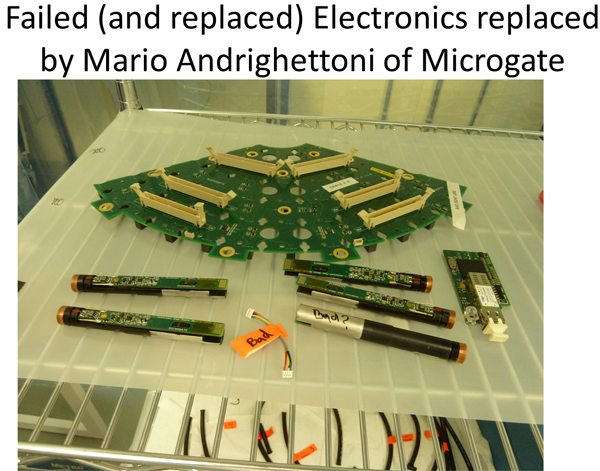

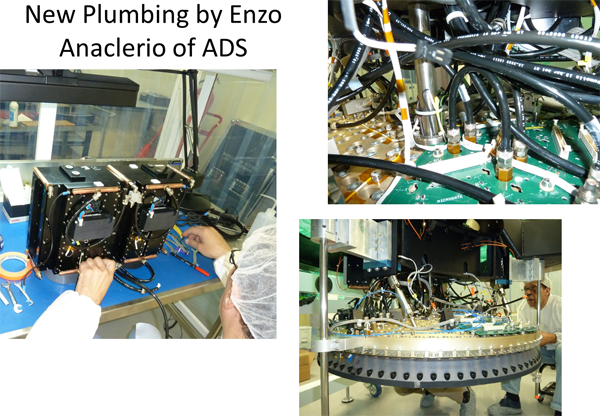

Therefore the ASM must be cooled when it is powered on. The cooling system is a set of hoses through which chilled glycol (antifreeze) is run. This is a common component of many instruments at the telescope. Unfortunately, MagAO had a glycol leak in February that caused our 2016A run to end early because it damaged the ASM. Runa and Marco came to save the day and help us get the shell unstuck to clean the glycol off the back.

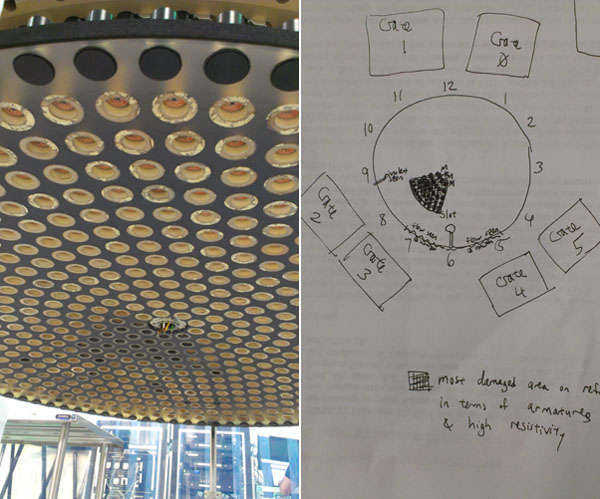

We spent a few days in the clean room getting the shell off the ASM led by Marco. Then Runa led us in cleaning the glycol residue off the back of the shell. We were able to inspect the reference body at this point, and saw that a group of armatures (the top of the capacitors that sense the position of the shell at each actuator’s location) had lost their silver coating due to an electrolysis reaction:

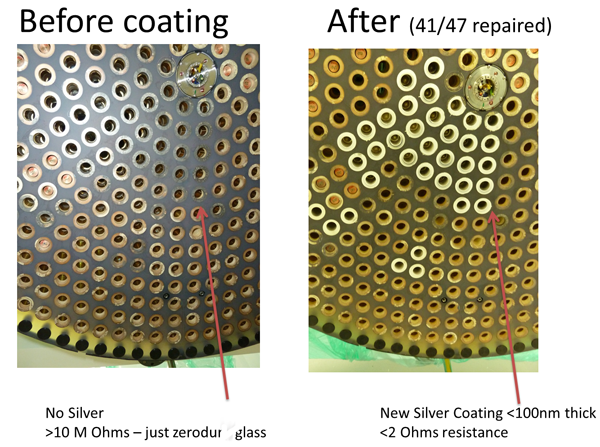

Laird and Brian Smith of Optical Sciences developed a new spray silver process to re-coat the armatures that had lost conductivity on the top of the capacative sensors:

Before and after the new spray silver coating was applied:

And a video of the spray silver technique:

Microgate and ADS personnel came out to assist in the refurbishment, as well as some LCO personnel. Here are Dave, Jared, and Mario inspecting the ASM in May:

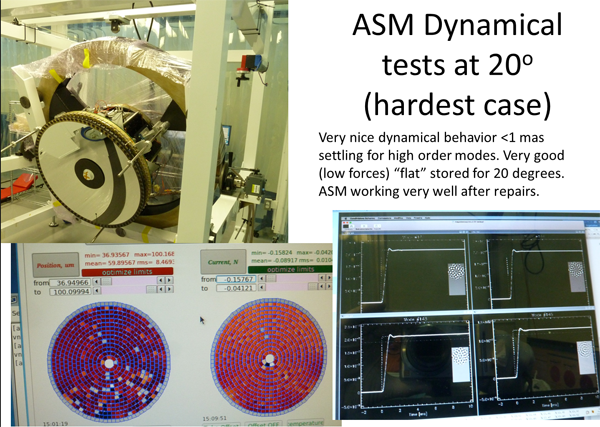

The ASM passed dynamical tests on that run:

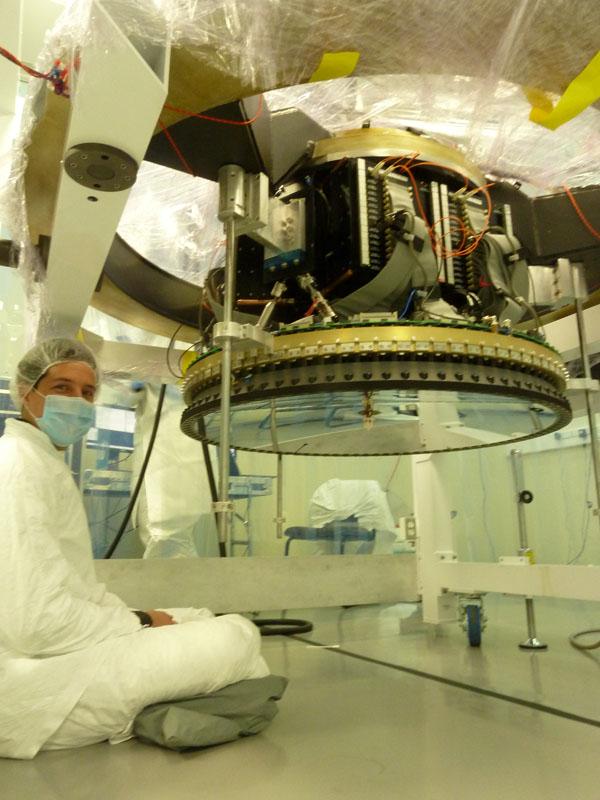

Here is how the bare ASM looks when most of the hoses and electronics have been removed:

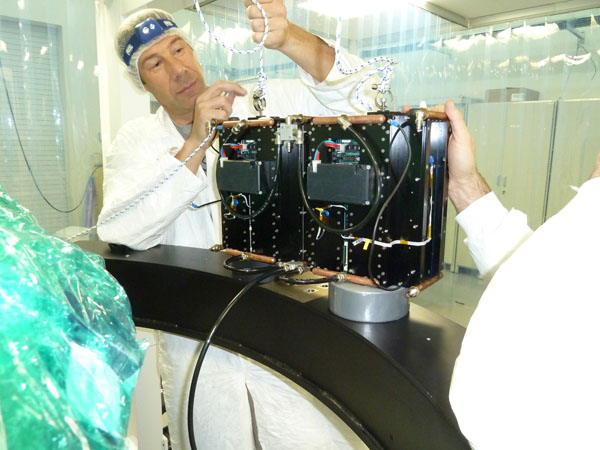

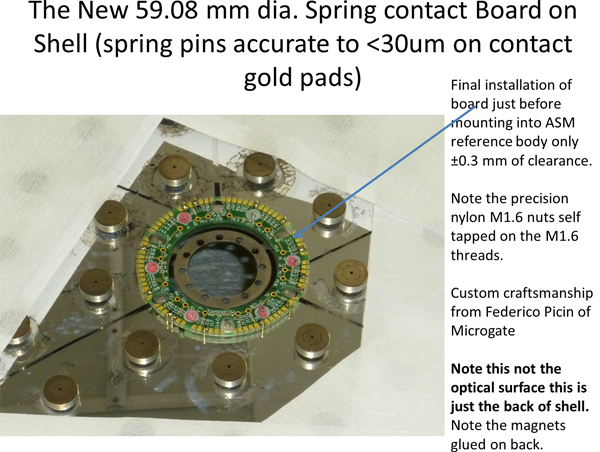

But we learned we still had to replace a board, which Federico of Microgate came to help with:

So why haven’t we heard about it on the blog yet? Well, we had to do a lot of work to repair the ASM from this leak, and we weren’t sure what the final state of the ASM and MagAO was going to be. We weren’t sure what to say… but now we have some good news! The ASM can be powered and controlled in a simulated closed loop! While we still have calibration work to do, this is a sign that our repairs have worked and we will be back on sky again soon! Again, here is a 5-second video showing the MagAO ASM running again:

Hooray!

And thanks to Rob Simcoe for use of the FIRE chiller to keep the ASM cool through the new hoses while testing in the clean room:

Fewer than 219 songs of the days: