It’s been a very busy 6 weeks since we passed PSR and received the approval to ship out MagAO-X. In those 6 weeks, we’ve been working on putting the final touches for the instrument. On October 2, we were scheduled for moving the MagAO-X instrument into its shipping crate, which means lots and lots of preparation for the big day.

It’s been all-hands-on-deck with many days and late nights in the lab carefully packing the instrument and the electronics rack. Alex H and Maggie have been helping Laird with locking down all the optics on the table for minimal shifting through the transport process. Joseph, Kyle, Alex R, and I have been helping Jared with migrating the electronics from the lab rack to the MagAO-X shipping rack. Jared, Joseph, and Kyle have been working on integrating the hardware and software from the newly migrated electronics rack to the locked down testbed. The XWCL room was raining zip ties, velcro ties, and cut styrofoam for weeks. We ran out of label maker tape on the day we were packing up the instrument.

In case you missed all the fun, here’s some photos from the shipping preparation in the lab:

MagAO-X PI handling the scary BMC 2K ribbon cables

Plenty of raining styrofoam for the cable channel routing

Electronics side panel close-up

The AO controller battlestation is LCO ready!

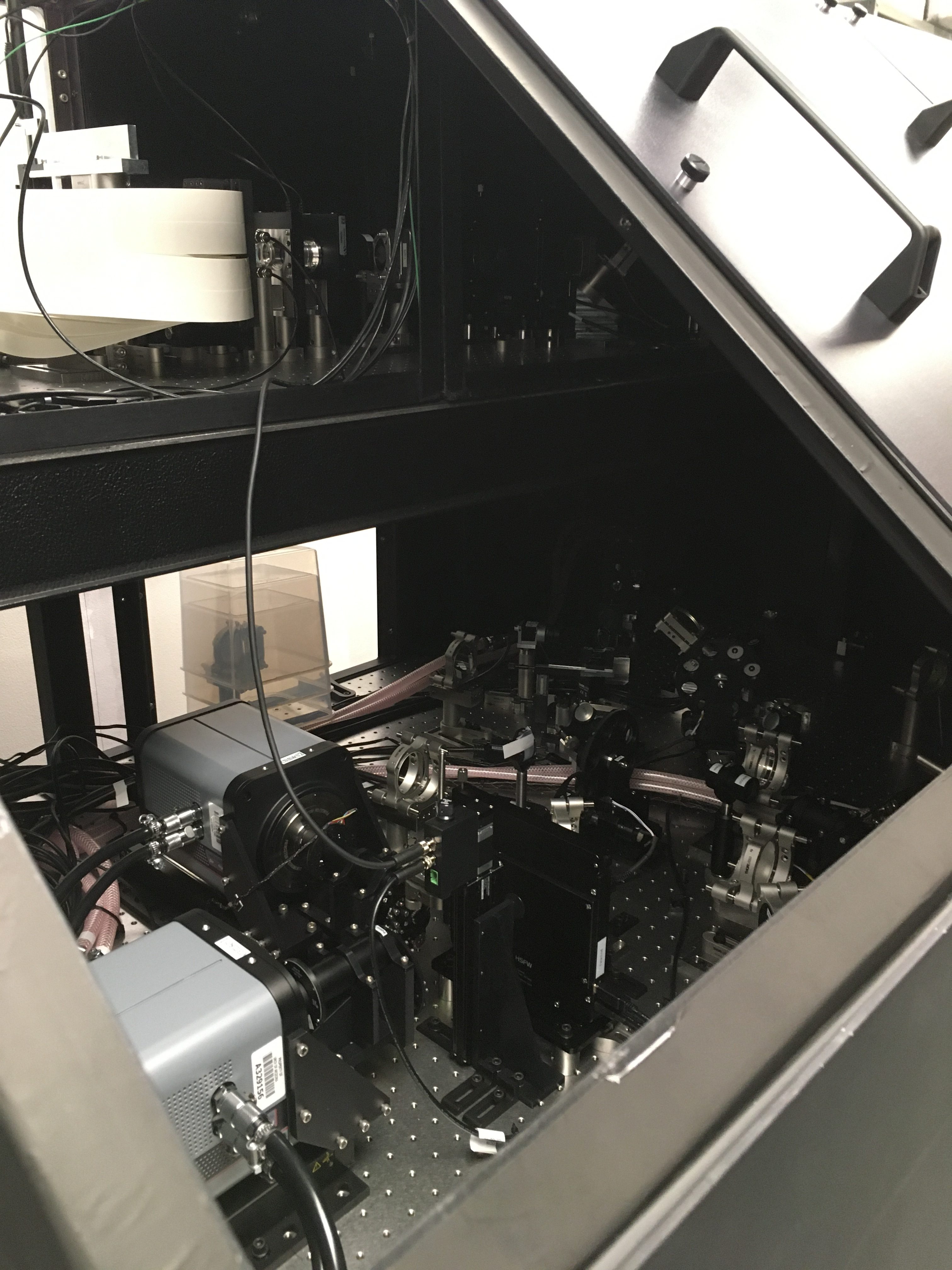

One last look at MagAO-X’s optics guts

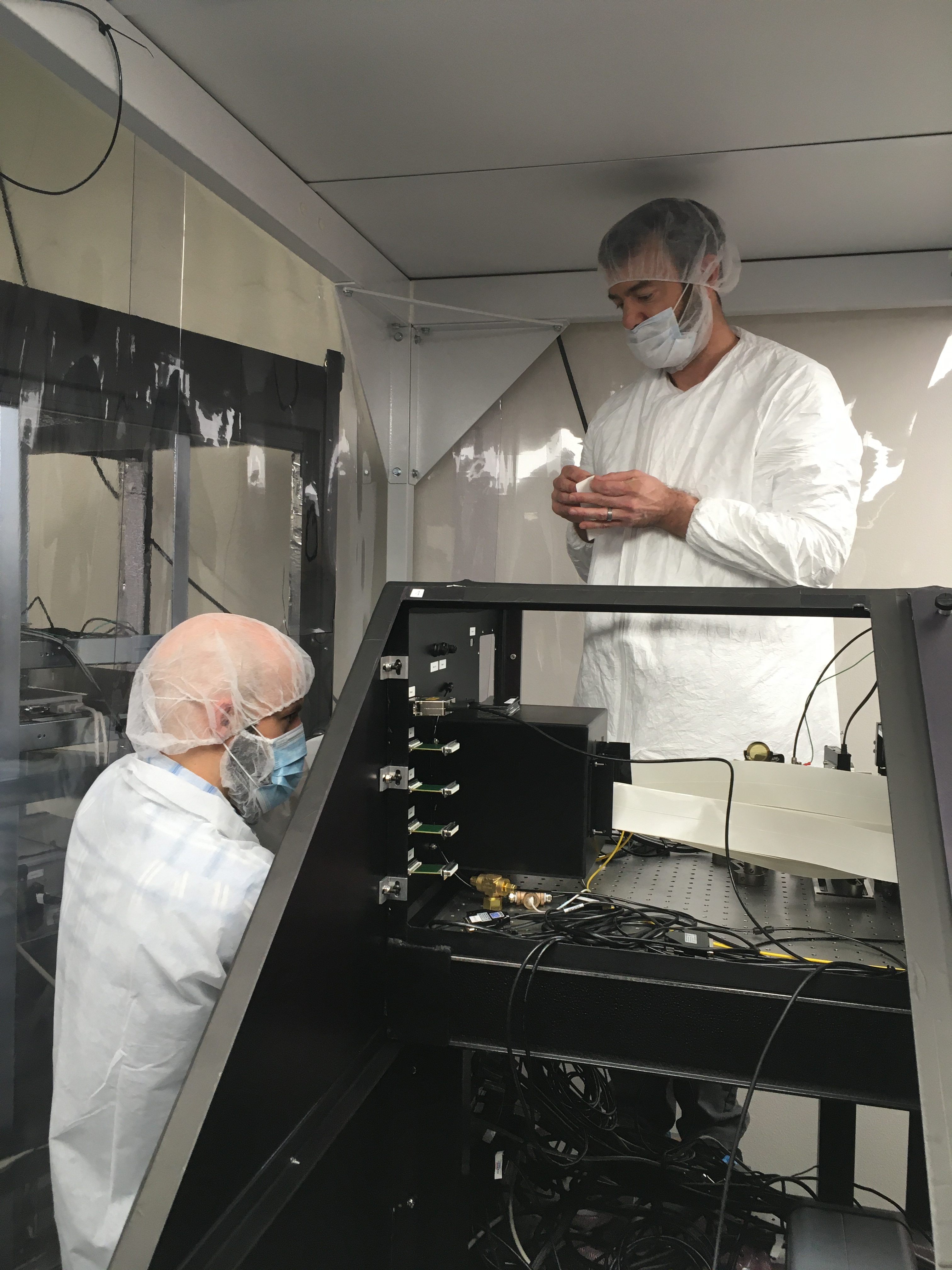

Jared and Kyle prepping the ports for the BMC 2K

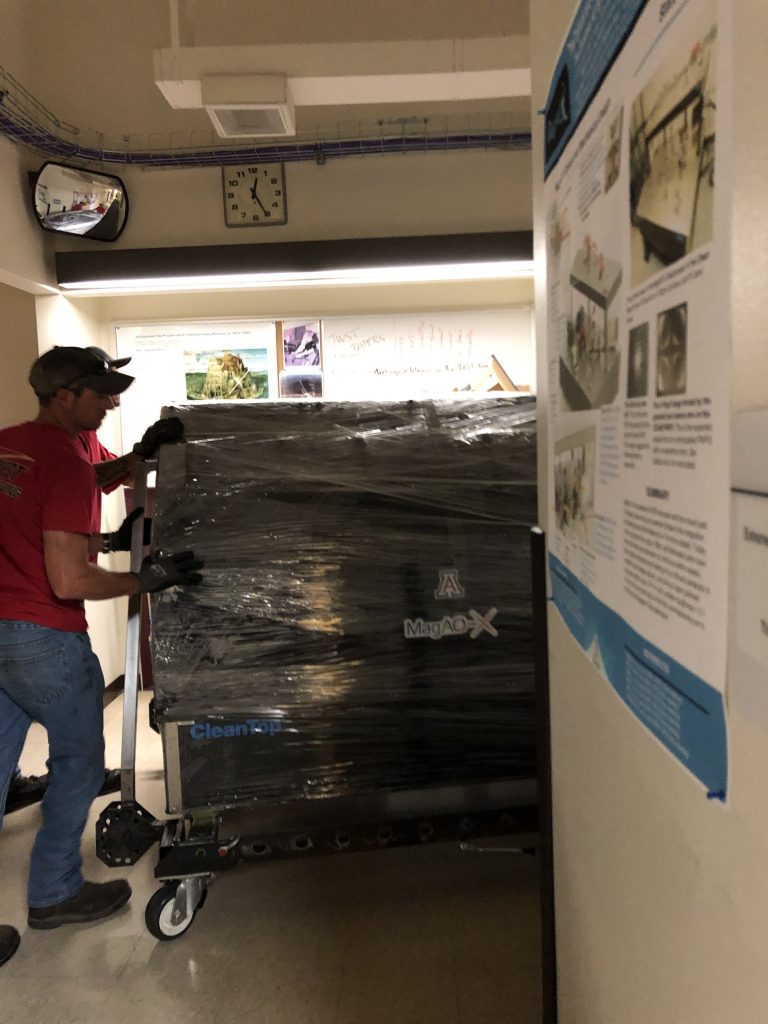

The final touch for moving MagAO-X to its shipping crate was wrapping it in lots of plastic:

October 2 was a big milestone step for MagAO-X, the day it made its first move out of the XWCL room in Steward. However, it only moved down 1 floor (XWCL is on the 2nd floor, and the loading dock is in the 1st floor / basement). It may not seem far in MagAO-X’s journey, but it took lots of effort… in addition to the freight elevator breaking the day before. Jared, Laird, Alexes R and H, Kyle, Jamison, Nick, Victor, and I were present all day for the big event.

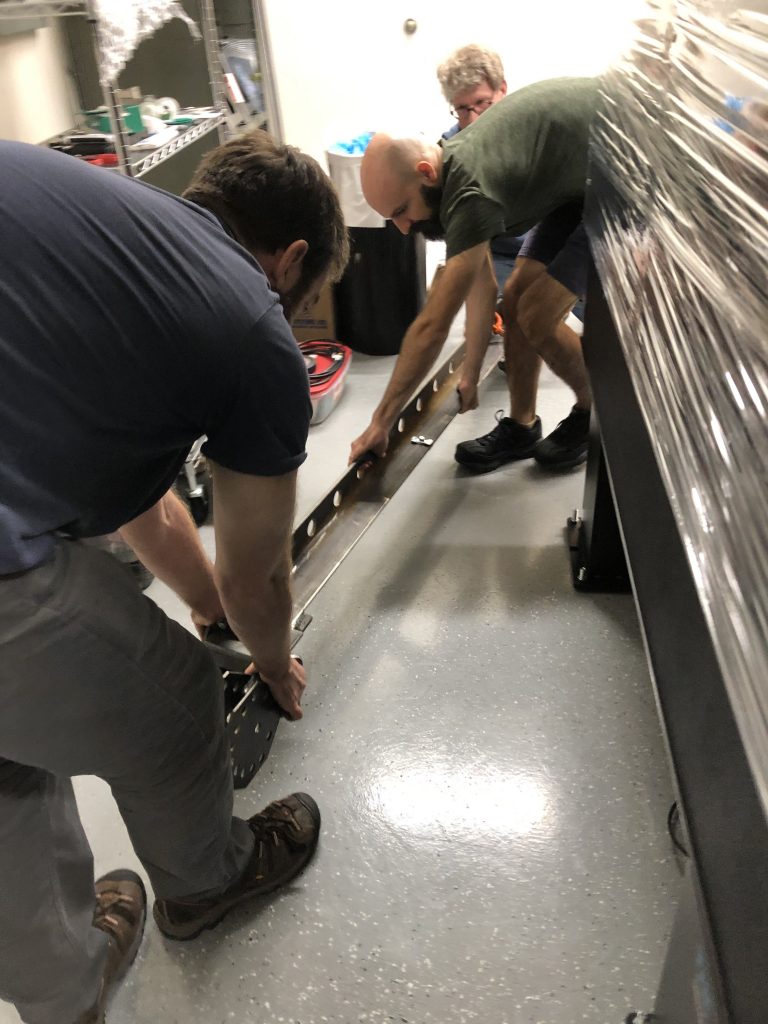

First thing we did was get the (new and lighter) cart onto the testbed:

Disassembling the new cart’s handles

Unlocking one side of the cart

Moving one rail to the other side of the table

Getting the fit ready for the movers

Next, the riggers arrived to lift up MagAO-X from its legs and onto the cart:

MagAO-X PI checking the cart handle bolts

It’s ready to go outside the lab!

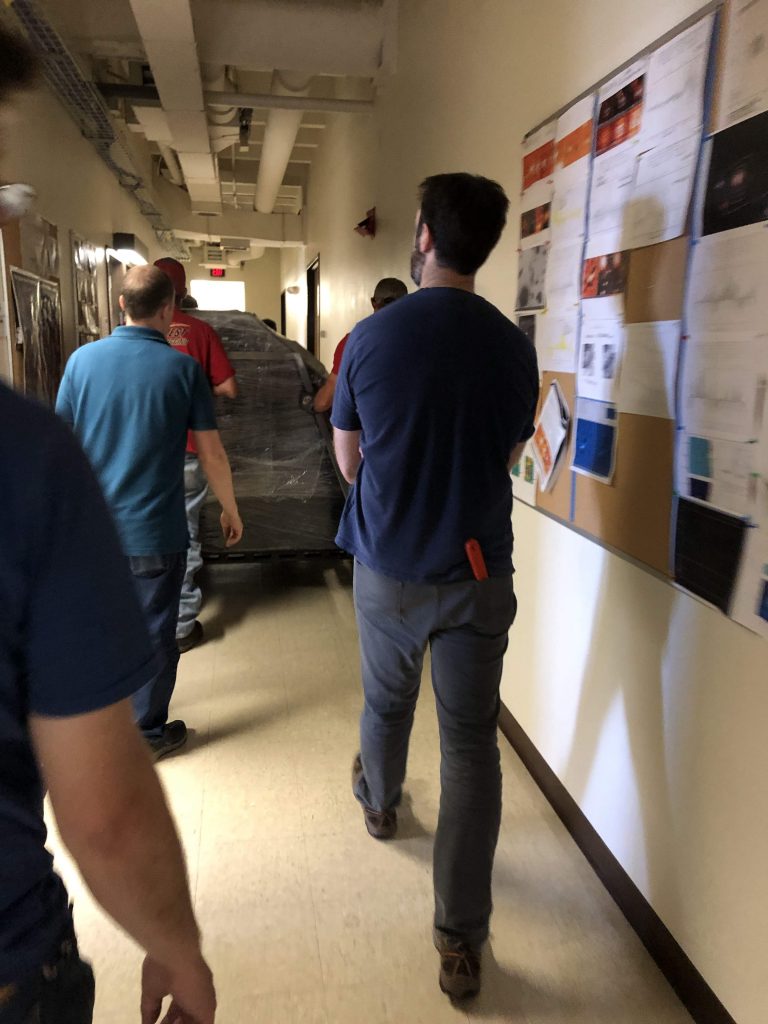

Then, it took a journey down the hallway to the freight elevator to go to the basement’s loading dock: (Shoutout to facilities for making sure the freight elevator worked that day no matter what!)

MagAO-X made the tight turn!

MagAO-X PI following the cart down the hall to the freight elevator

In the basement, it was carted to the loading dock area:

Moving MagAO-X through the basement

On its way to the loading dock!

The shipping crate was waiting for the instrument inside the building by the loading dock. We needed to push the shipping crate outside to the loading dock first to make room for MagAO-X:

Out in the loading dock area, a crane came by and to remove the crate’s cover:

Inside the crate was the testbed’s shipping frame to maintain balance for MagAO-X. Jamison presented these at PSR. The PSR drawings don’t look fancy, but seeing them in person is super legit:

We wheeled out MagAO-X for it to be craned onto the shipping frame:

Jared and Laird leading MagAO-X to the light of day

Setting the crane up with the instrument

However, like all great projects, no matter the extent of our preparation, we encountered some issues with hardware. While fixing that, we encountered another issue – MagAO-X started overheating after exposure to the sun. The black metal panels absorbed lots of heat and the plastic wrap encouraged a greenhouse effect. So, we wheeled it back inside the building to let it cool down:

When the hardware issues were cleared, we wheeled MagAO-X back outside and the exciting crane process began:

Out you go again…

MagAO-X PI watching the lifted instrument line up with the shipping frame

MagAO-X PI watching the fine lining up

Victor and Alex R removing the cart after the testbed was connected to the shipping frame

With MagAO-X craned onto its shipping frame and bolted down, the crate cover was craned back to enclose the instrument:

We boxed up the instrument and wheeled the packed crate back inside Steward, where it has stayed for a week before it ships out:

Jared trying to stop Kyle from getting squished

The crate is back in its original spot, but this time with the cargo inside

Within that week timeframe, we continued on with the shipping process. Two days were spent in the Mirror Lab for getting the electronics rack in its shipping crate. We began packing and inventorying all the equipment to send down to Chile:

We modified one of the shipping crate’s side panels to add more viewing windows. Here’s one last look at MagAO-X in its crate, before it gets shipped off to Chile:

I’ve been working off-and-on MagAO-X since January 2017 on the simulation side doing Fresnel propagation analysis. Working in simulation means you don’t get a lot of interaction with the hardware. I got to see the instrument close up while helping in the shipping process, and it has been a rewarding learning experience. (Plus, my arts and crafts hobby finally became useful with lots of foam cutting, my heart was singing in delight for days) I’ve learned a lot with the team, and I’m sure we’re going to learn more as we continue on the next step of the shipping process.

The MagAO-X PI has rules. It is not necessarily a rule, but rather a recommendation to have a quote:

Jared: Stop having fun, this isn’t fun

The rule is having a song. I picked this one because it’s so strange adjusting to the change of not having MagAO-X in the lab after 2 years: